For more than 30 years, Skoberne has been a leading manufacturer of plastic flue gas pipes and we are recognised for our exhaust gas systems for condensing boilers.

An overview of the benefits of plastic flue gas pipe products

- Durability

- Resistance to acidic condensates

- Insensitive to the effects of thermal cycling of condensing

- Easy repairs thank to simple push fit functionality

We have the right plastic flue pipe for every nationally and internationally recognised operating method:

- Single-wall - rigid

- Single-wall - flexible

- Concentric pipe (flue gas exhaust and air supply system)

These can be easily combined with each other and/or expanded, depending on the situation and requirement. As a result, unusual construction situations can also be overcome.

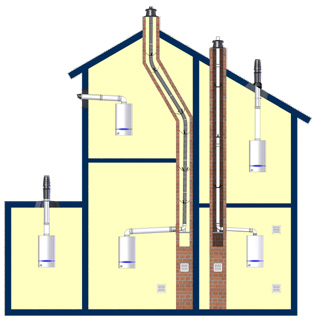

The sketch shows examples of some typical installations:

Product characteristics and applications

of Skoberne’s plastic flue gas pipes

- Fuel: Oil or gas

- Operating mode: single wall and concentric (open vent or room sealed)

- Flue gas temperatures: up to 120°C

- Operating pressure: Positive and negative pressure

- Pressure class: P1 and H1

- Fire protection: "Flame retardant" (formerly DIN 4102 B1)

- UV resistance: stabilised

- Nominal diameters:

- Single wall rigid: range from 60mm to 315mm

- Flexible pipe: 60mm, 80mm, 110mm

- Concentric 60/100, 80/125, 110/150, 110/160

- TÜV-certified quality product made in Germany

You can find out more in our Technical Guide and Installation Instructions in the Download area.

Examples of different applications